In the ever-evolving world of precision engineering, CNC Electrical Discharge Machining EDM has established itself as a go-to solution for working with materials that challenge traditional machining methods. Known for its ability to shape hard metals and intricate designs with high accuracy, CNC EDM is a technology that continues to transform manufacturing across a wide array of industries.

Unmatched Precision for Hard-to-Machine Materials

CNC EDM works by using electrical discharges to erode material in a controlled manner. This process makes it ideal for cutting tough and heat-resistant metals like titanium, Inconel, and hardened tool steels materials that are notoriously difficult to cut using conventional tools.

Key Advantages:

- No direct contact between tool and material

- Maintains material integrity by avoiding heat deformation

- Allows for extremely tight tolerances

Because of its non-contact machining process, CNC EDM leaves surfaces smooth and accurate, minimizing the need for additional finishing steps.

Complex Geometry Made Simple

One of the standout features of Uneed CNC EDM is its capacity to produce intricate and highly detailed shapes. Whether you are creating micro-sized holes or complex contours, EDM excels where other machines fall short.

Applications include:

- Injection mold cavities with fine details

- Aerospace components with tight geometrical specs

- Medical tools requiring micro-precision

EDM’s capability to cut internal corners and deep recesses makes it essential for jobs requiring high levels of complexity, especially when tolerances must be maintained within microns.

Versatile Types of CNC EDM

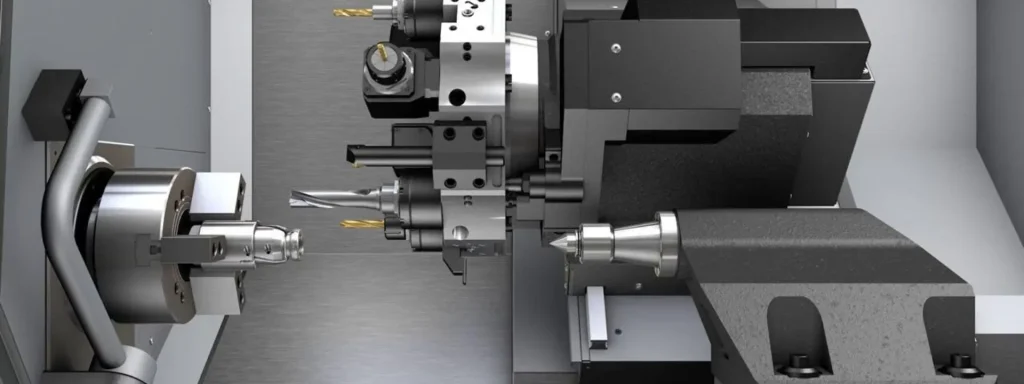

There are two main types of CNC EDM: Wire EDM and Sinker EDM. Each serves a unique purpose depending on the application:

- Wire EDM: Ideal for cutting through thick materials with fine precision using a continuously fed wire.

- Sinker EDM: Perfect for creating complex cavities using custom-shaped electrodes.

Both types share the core advantage of delivering exceptional repeatability, making CNC EDM suitable for both prototypes and high-volume production.

Efficiency That Enhances Productivity

While CNC EDM might have a slower cutting speed than traditional methods, its unmatched accuracy, minimal tool wear, and low manual intervention make it highly efficient over the long run. With the integration of modern automation and advanced software, EDM systems can now operate continuously with minimal supervision, boosting productivity and reducing human error.

Supporting Innovation across Industries

From aerospace to electronics, and from medical devices to precision molds, CNC EDM is empowering industries to design without limits. Manufacturers benefit from greater design flexibility and the ability to work with difficult materials, helping them stay ahead in competitive markets.

Final Thoughts

CNC EDM continues to redefine what is possible in precision machining. Its ability to deliver ultra-accurate cuts in the hardest and most complex materials makes it indispensable for modern manufacturing. With its versatility, reliability, and design freedom, CNC EDM is not just a technology of today it is an essential force shaping the future of engineering.